目录

蛋白质水解在运动营养中的好处

蛋白质水解是将蛋白质分解成更小的肽和氨基酸的过程。这一过程常用于运动营养中,以增强人体对蛋白质的吸收和利用。通过将蛋白质分解成更小的成分,蛋白质水解可以帮助提高氨基酸的生物利用度,而氨基酸是肌肉组织的组成部分。

运动营养中蛋白质水解的主要好处之一是它能够加速消化和吸收。蛋白质的吸收。当蛋白质分解成更小的肽和氨基酸时,它们可以更快地被身体吸收,从而更快地将营养物质输送到肌肉。这对于剧烈运动后需要快速补充蛋白质储备的运动员和活跃人士特别有益。

除了提高蛋白质吸收速度外,蛋白质水解还可以提高蛋白质利用的整体效率。通过将蛋白质分解成更小的成分,身体可以更容易地获取和利用肌肉修复和生长所需的氨基酸。这可以帮助运动员更快地从锻炼中恢复并更有效地增强肌肉质量。

蛋白质水解在运动营养中的另一个优点是它有可能降低消化不适的风险。有些人在摄入大量完整蛋白质时可能会出现腹胀、胀气或其他消化问题。通过将蛋白质分解成更小的肽和氨基酸,蛋白质水解可以帮助缓解这些症状,并使消化系统敏感的个体更能耐受蛋白质补充剂。

此外,蛋白质水解还可以改善蛋白质补充剂的味道和质地。有些人发现,与完整蛋白质相比,水解蛋白质具有更温和的味道和更光滑的稠度,使它们更美味且更容易食用。这对于那些难以仅通过天然食物来满足蛋白质需求的运动员来说尤其有益。

总的来说,蛋白质水解为寻求优化蛋白质摄入量的运动员和活跃人士提供了一系列好处。通过提高蛋白质吸收的速度和效率,减少消化不适,并增强蛋白质补充剂的味道和质地,蛋白质水解可以帮助支持肌肉恢复、生长和整体表现。

总而言之,蛋白质水解是一种有价值的工具运动营养可以帮助运动员和活跃人士最大限度地发挥蛋白质补充的好处。通过将蛋白质分解成更小的肽和氨基酸,蛋白质水解可以提高蛋白质吸收的速度和效率,减少消化不适,并增强蛋白质补充剂的味道和质地。无论您是想从锻炼中更快地恢复、增强肌肉质量,还是只是更有效地满足您的蛋白质需求,蛋白质水解都可以成为您运动营养方案的宝贵补充。

提高消化率的蛋白质水解

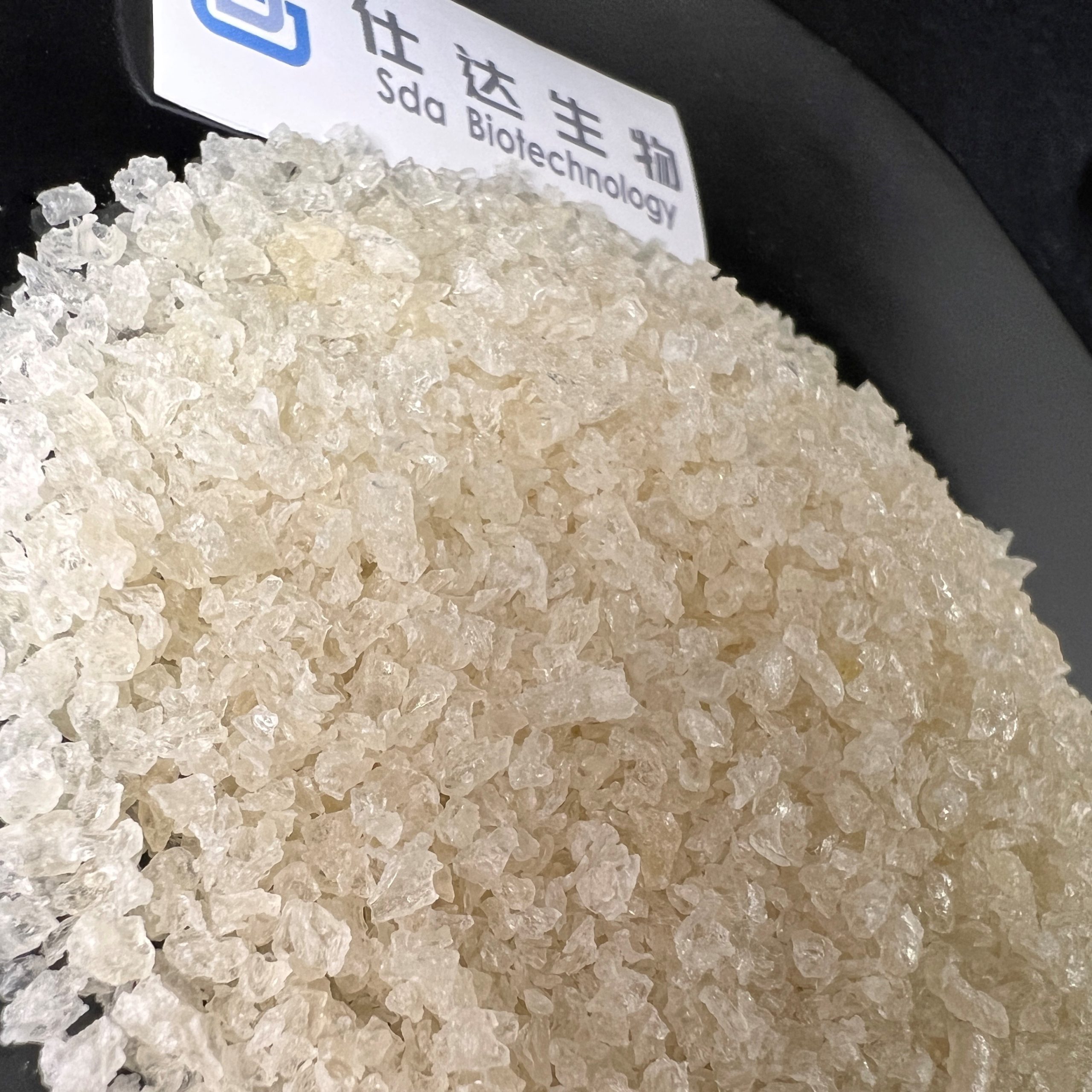

蛋白质水解是将蛋白质分解成更小的肽和氨基酸的过程。该过程通常用于食品工业,以提高蛋白质的消化率并增强其功能特性。蛋白质水解可以通过酶解、酸解、碱解等多种方法实现。

| 项目 | 单位 | 标准要求 | 结果 | 评价 | |||||||

| 感官评价 | / | 白色或淡黄色 | 白色 | 合格 | |||||||

| / | 产品的味道、气味应有,无异味 | 无异味 | 合格 | ||||||||

| / | Powdery,without lumps,and without foreign objects | Powdered, without lumps or foreign objects | Qualified | ||||||||

| Protein,(%) | % | ≥90 | 98.7 | Qualified | |||||||

| Hydroxyproline | g/100g | ≥3.0 | 7.1 | Qualified | |||||||

| Total nitrogen | g/100g | ≥15.0 | 17.9 | Qualified | |||||||

| Ash,(%) | g/100g | ≤7.0 | 0.5 | Qualified | |||||||

| Moisture,(%) | g/100g | ≤7.0 | 6.34 | Qualified | |||||||

| Transparency | 450nm | ≥70 | 86 | Qualified | |||||||

| 620nm | ≥85 | 93 | Qualified | ||||||||

Protein hydrolysates produced through enzymatic hydrolysis have several advantages over intact proteins. They are easier to digest, as the proteins have been broken Down into smaller peptides and amino acids. This makes them suitable for individuals with digestive issues or sensitivities to certain proteins. Protein hydrolysates are also more soluble and have improved emulsifying and foaming properties, making them ideal for use in food products such as Beverages, Dairy Products, and Baked Goods.

In addition to improving digestibility, protein hydrolysates have been shown to have other health benefits. They are often used in Sports Nutrition products as they are quickly absorbed by the body and can help with muscle recovery and growth. Protein hydrolysates are also used in medical nutrition products for individuals with conditions that require easily digestible proteins, such as malnutrition or gastrointestinal disorders.

Acid hydrolysis and alkaline hydrolysis are alternative methods for protein hydrolysis, but they are less commonly used in the food industry. Acid hydrolysis involves the use of acids such as hydrochloric acid or sulfuric acid to break down proteins. This method is more harsh and can denature the proteins, affecting their functional properties. Alkaline hydrolysis, on the other hand, uses alkaline substances such as sodium hydroxide to break down proteins. While alkaline hydrolysis is gentler than acid hydrolysis, it can also affect the flavor and color of the proteins.

Despite their drawbacks, acid and alkaline hydrolysis are still used in certain applications where enzymatic hydrolysis is not suitable. For example, acid hydrolysis is used in the production of gelatin from Collagen, while alkaline hydrolysis is used in the production of soy protein isolates. These methods are more cost-effective and can be scaled up for industrial production.

In conclusion, protein hydrolysis is a valuable process in the food industry for improving the digestibility and functional properties of proteins. Enzymatic hydrolysis is the preferred method due to its efficiency and specificity, but acid and alkaline hydrolysis are also used in certain applications. Protein hydrolysates have a wide range of uses in food products, sports nutrition, and medical nutrition, making them a versatile ingredient for improving the nutritional quality of foods.

Protein Hydrolysis in Food Industry for Flavor Enhancement

Protein hydrolysis is a process that is widely used in the food industry for flavor enhancement. This process involves breaking down proteins into smaller peptides and amino acids through the use of Enzymes or acids. The resulting hydrolyzed proteins have a number of applications in the food industry, including as flavor enhancers, Nutritional Supplements, and functional ingredients.

One of the main uses of protein hydrolysis in the food industry is for flavor enhancement. When proteins are hydrolyzed, the peptides and amino acids that are produced have a savory, umami flavor that can enhance the overall taste of a food product. This is particularly useful in products such as soups, sauces, and Snacks, where a rich and savory flavor is desired.

In addition to enhancing flavor, hydrolyzed proteins can also improve the texture and mouthfeel of food products. The peptides and amino acids produced during hydrolysis can act as emulsifiers, Stabilizers, and thickeners, helping to create a smooth and creamy texture in products such as sauces, dressings, and dairy products.

Another important use of protein hydrolysis in the food industry is as a source of functional ingredients. Hydrolyzed proteins are rich in peptides and amino acids that have a number of health benefits, including improved digestion, muscle recovery, and immune function. As a result, hydrolyzed proteins are often used in nutritional supplements, sports drinks, and meal replacement products.

Protein hydrolysis is also used in the production of hydrolyzed vegetable proteins (HVP), which are commonly used as flavor enhancers in vegetarian and vegan food products. HVPs are made by hydrolyzing proteins from sources such as soy, Wheat, and Corn, and are used to add a savory flavor to products such as meat substitutes, snacks, and condiments.

Overall, protein hydrolysis is a versatile process that has a wide range of uses in the food industry. From enhancing flavor and texture to providing functional ingredients and nutritional benefits, hydrolyzed proteins play a key role in the development of innovative and delicious food products. As consumer demand for healthier and more flavorful foods continues to grow, protein hydrolysis will likely become an even more important tool for food manufacturers looking to create products that meet the needs and preferences of today’s consumers.