Table of Contents

Importance of Casing and Tubing in Wellhead Systems

A wellhead is a crucial component of any oil or gas well, serving as the interface between the subsurface reservoir and the surface production facilities. It plays a vital role in controlling the flow of fluids from the reservoir to the surface, as well as providing a means of monitoring and controlling pressure within the well. A wellhead typically consists of several key components, each of which plays a specific role in ensuring the safe and efficient operation of the well.

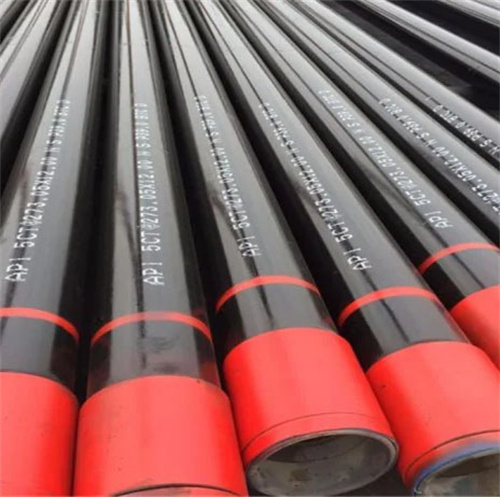

One of the primary components of a wellhead system is the casing. Casing is a series of Steel Pipes that are inserted into the wellbore to provide structural support and prevent the collapse of the wellbore walls. Casing also serves to isolate different formations within the well, preventing the mixing of fluids and ensuring the integrity of the well. In addition, casing helps to control the flow of fluids within the well, allowing for the safe and efficient extraction of oil or gas.

Another important component of a wellhead system is tubing. Tubing is a smaller diameter pipe that is inserted into the casing to transport fluids from the reservoir to the surface. Tubing is typically made of steel or other corrosion-resistant materials to withstand the harsh conditions found in oil and gas wells. Tubing also provides a means of injecting Chemicals or other substances into the well, as well as allowing for the installation of downhole equipment such as Pumps or Sensors.

Casing and tubing work together to ensure the safe and efficient operation of a wellhead system. Casing provides structural support and isolates different formations within the well, while tubing allows for the extraction of fluids from the reservoir. Together, these components help to maintain the integrity of the well and ensure the safe and efficient production of oil or gas.

In addition to casing and tubing, a wellhead system also includes other important components such as a blowout preventer (BOP) and a Christmas tree. A blowout preventer is a Safety device that is installed on top of the wellhead to prevent the uncontrolled release of fluids from the well. It consists of a series of Valves that can be closed in the event of a blowout, sealing off the well and preventing the escape of fluids.

A Christmas tree is a series of valves and fittings that are installed on top of the wellhead to control the flow of fluids from the well. It typically includes a series of valves that can be opened or closed to regulate the flow of fluids, as well as fittings for connecting to production equipment such as pipelines or storage tanks. The Christmas tree also provides a means of monitoring pressure and temperature within the well, allowing for the safe and efficient operation of the wellhead system.

In conclusion, casing and tubing are essential components of a wellhead system, providing structural support, isolating formations, and allowing for the extraction of fluids from the reservoir. Together with other components such as blowout preventers and Christmas trees, they help to ensure the safe and efficient operation of oil and gas wells. By understanding the importance of these components, operators can ensure the integrity and reliability of their wellhead systems, leading to increased production and improved safety.

Understanding the Function of the Christmas Tree in Wellhead Operations

A wellhead is a crucial component in the oil and gas industry, serving as the primary interface between the surface and the subsurface of a well. It plays a vital role in controlling the flow of fluids from the reservoir to the surface, as well as providing a means of monitoring and controlling the well during production. One of the key components of a wellhead is the Christmas tree, which is essential for wellhead operations.

The Christmas tree is a complex assembly of valves, spools, and fittings that are installed on top of the wellhead to control the flow of fluids during production. It is named for its shape, which resembles a Christmas tree when fully assembled. The Christmas tree serves as the primary control point for the well, allowing operators to regulate the flow of oil and gas, as well as monitor pressure and temperature Levels.

The main components of a Christmas tree include the master valve, wing valve, choke valve, and kill valve. The master valve is the primary shut-off valve that controls the flow of fluids from the well. The wing valve is used to isolate the Christmas tree from the rest of the wellhead system, while the choke valve is used to regulate the flow of fluids during production. The kill valve is a safety valve that is used to shut off the well in case of an emergency.

In addition to these valves, the Christmas tree also includes a number of other components, such as pressure Gauges, Temperature Sensors, and control panels. These components are used to monitor and control the well during production, ensuring that it operates safely and efficiently. The Christmas tree is typically equipped with a number of safety features, such as pressure relief valves and emergency shut-off systems, to prevent accidents and protect personnel and equipment.

The Christmas tree is typically installed on top of the wellhead using a series of Flanges and Bolts. It is connected to the wellhead using a series of high-pressure fittings and Seals to ensure a tight and secure connection. The Christmas tree is designed to withstand high pressures and temperatures, as well as harsh environmental conditions, making it a critical component in wellhead operations.

Overall, the Christmas tree plays a crucial role in wellhead operations, serving as the primary control point for the well and allowing operators to regulate the flow of fluids during production. It is equipped with a number of valves, sensors, and safety features to ensure that the well operates safely and efficiently. By understanding the function of the Christmas tree and its components, operators can ensure that their wellhead operations run smoothly and effectively.