Table of Contents

Benefits of Using Seamless Line Pipe in Oil and Gas Industry

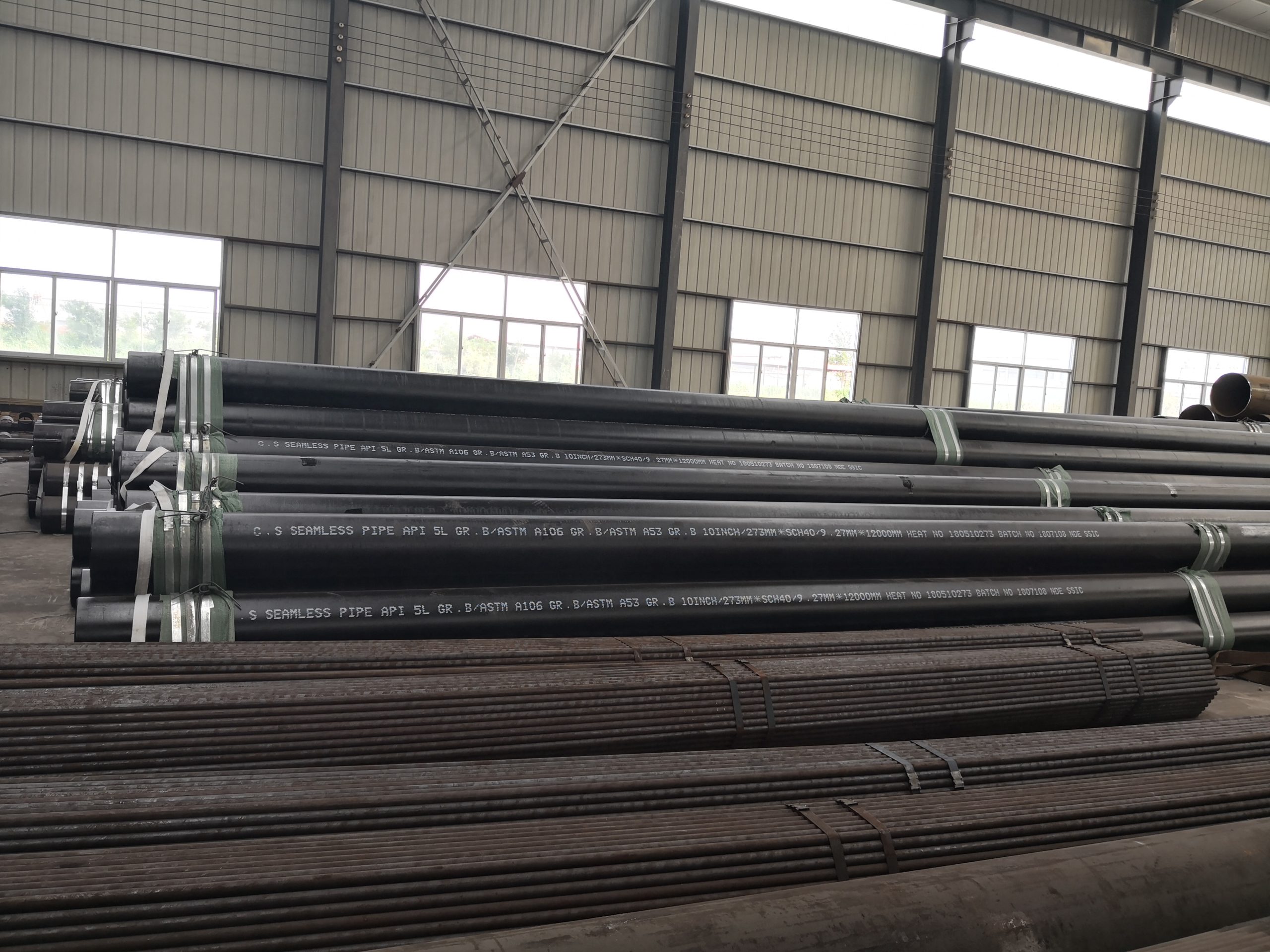

Seamless line pipe is a critical component in the oil and gas industry, playing a crucial role in the transportation of oil and gas from production sites to refineries and distribution centers. Unlike welded line pipe, which is made by welding together multiple pieces of steel, seamless line pipe is made from a single piece of steel that is heated and stretched to form a seamless tube. This manufacturing process results in a pipe that is stronger, more durable, and better suited for the high-pressure and high-temperature environments commonly found in the oil and gas industry.

One of the key benefits of using seamless line pipe in the oil and gas industry is its superior strength and durability. Because seamless line pipe is made from a single piece of steel, it is less prone to defects and weaknesses that can occur in welded line pipe. This makes seamless line pipe better able to withstand the extreme pressures and temperatures that are often encountered in oil and gas pipelines, reducing the risk of leaks, ruptures, and other failures that can result in costly downtime and environmental damage.

In addition to its strength and durability, seamless line pipe also offers improved corrosion resistance compared to welded line pipe. The seamless manufacturing process eliminates the need for welding, which can create weak points in the pipe where corrosion can occur. This makes seamless line pipe better able to resist the corrosive effects of the oil, gas, and other substances that flow through it, extending the lifespan of the pipe and reducing the need for costly maintenance and repairs.

Another benefit of using seamless line pipe in the oil and gas industry is its smooth interior surface. Because seamless line pipe is made from a single piece of steel, it has a uniform wall thickness and a smooth interior surface that allows for more efficient flow of oil and gas. This reduces friction and turbulence in the pipeline, which can help to improve the overall efficiency of the transportation system and reduce energy consumption. In addition, the smooth interior surface of seamless line pipe also helps to reduce the risk of blockages and buildup that can occur in pipelines with rough or uneven surfaces.

Furthermore, seamless line pipe is also easier to install and maintain than welded line pipe. Because seamless line pipe is made from a single piece of steel, it is more flexible and easier to bend and shape to fit the contours of the terrain. This can help to reduce the time and cost of installation, as well as minimize the need for welding and other specialized equipment. Additionally, the smooth interior surface of seamless line pipe makes it easier to inspect and clean, reducing the risk of contamination and ensuring the safe and efficient operation of the pipeline.

In conclusion, seamless line pipe offers a number of benefits for the oil and gas industry, including superior strength and durability, improved corrosion resistance, smooth interior surface, and ease of installation and maintenance. By choosing seamless line pipe for their pipelines, oil and gas companies can improve the reliability, efficiency, and Safety of their transportation systems, ultimately helping to reduce costs and minimize environmental impact.

How to Choose the Right Seamless Line Pipe for Your Project

Seamless line pipes are an essential component in various industries, including oil and gas, petrochemical, and water transportation. These pipes are designed to transport fluids and gases under high pressure and temperature conditions. Choosing the right seamless line pipe for your project is crucial to ensure the safety and efficiency of your operations.

https://www.youtube.com/watch?v=6tUfn1bKo9YWhen selecting a seamless line pipe, there are several factors to consider. The first consideration is the material of the pipe. Seamless line pipes are typically made from Carbon Steel, Stainless Steel, or Alloy Steel. Each material has its own unique properties and is suitable for different applications. Carbon Steel Pipes are commonly used in high-pressure and high-temperature environments, while Stainless Steel Pipes are preferred for corrosive environments. Alloy steel pipes are ideal for applications that require high strength and resistance to wear and tear.

Another important factor to consider when choosing a seamless line pipe is the size and thickness of the pipe. The size of the pipe is determined by the diameter and wall thickness. The diameter of the pipe is measured in inches, while the wall thickness is measured in inches or millimeters. The size and thickness of the pipe will depend on the pressure and temperature requirements of your project. It is essential to consult with a professional engineer to determine the appropriate size and thickness of the pipe for your specific application.

In addition to material, size, and thickness, it is also important to consider the manufacturing process of the seamless line pipe. Seamless pipes are manufactured using a process called hot extrusion or cold drawing. Hot extrusion involves heating a solid billet and forcing it through a die to form a seamless pipe. Cold drawing involves pulling a solid billet through a series of dies to reduce its diameter and form a seamless pipe. The manufacturing process will affect the quality and performance of the pipe, so it is important to choose a reputable manufacturer with a proven track record of producing high-quality seamless line pipes.

Furthermore, it is essential to consider the coating and lining of the seamless line pipe. Coating and lining are applied to the pipe to protect it from corrosion, abrasion, and other forms of damage. Common coatings and linings include epoxy, polyethylene, and polyurethane. The type of coating and lining will depend on the environmental conditions and the type of fluid or gas being transported through the pipe. It is important to select a coating and lining that is compatible with the material of the pipe and the operating conditions of your project.

In conclusion, choosing the right seamless line pipe for your project is essential to ensure the safety and efficiency of your operations. Consider factors such as material, size, thickness, manufacturing process, and coating and lining when selecting a seamless line pipe. Consult with a professional engineer and reputable manufacturer to determine the most suitable pipe for your specific application. By taking these factors into account, you can ensure the success of your project and the longevity of your seamless line pipe.