Table of Contents

Benefits of Using Oil Casing Pipe in Drilling Operations

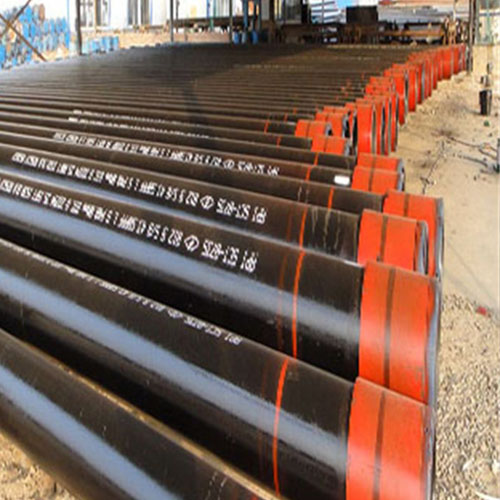

Oil casing pipe is an essential component in drilling operations, providing structural support and protection for the wellbore. Made from high-strength steel, oil casing pipe is designed to withstand the extreme pressures and temperatures encountered during drilling. In addition to its structural integrity, oil casing pipe also plays a crucial role in preventing contamination of the surrounding Environment and ensuring the efficient extraction of oil and gas reserves.

One of the key benefits of using oil casing pipe in drilling operations is its ability to prevent the collapse of the wellbore. As drilling progresses deeper into the earth, the pressure from the surrounding rock formations can cause the walls of the wellbore to collapse. This can Lead to costly delays and potentially dangerous situations for the drilling crew. By installing oil casing pipe, the wellbore is reinforced, providing a stable and secure environment for drilling to continue.

Another advantage of oil casing pipe is its ability to prevent the migration of fluids between different geological formations. During drilling, it is common for oil, gas, and other fluids to flow through the wellbore. Without proper containment, these fluids can mix with groundwater or other formations, leading to contamination and potential environmental damage. Oil casing pipe acts as a barrier, preventing the migration of fluids and ensuring that the extraction process is conducted safely and efficiently.

In addition to its structural and containment benefits, oil casing pipe also serves as a conduit for the extraction of oil and gas reserves. Once drilling is complete, the oil casing pipe is used to transport the extracted fluids to the surface for processing. The smooth interior surface of the pipe allows for efficient flow, minimizing pressure drop and maximizing production rates. This ensures that the valuable resources trapped beneath the earth’s surface can be extracted in a timely and cost-effective manner.

Furthermore, oil casing pipe is designed to withstand the harsh conditions encountered during drilling operations. From high temperatures to corrosive fluids, oil casing pipe is engineered to perform reliably in even the most challenging environments. This durability not only ensures the Safety of the drilling crew but also minimizes downtime and maintenance costs, leading to increased productivity and profitability for oil and gas companies.

Overall, the benefits of using oil casing pipe in drilling operations are clear. From providing structural support and containment to facilitating the extraction of oil and gas reserves, oil casing pipe plays a critical role in the success of drilling projects. Its ability to withstand extreme conditions, prevent contamination, and ensure efficient production make it an indispensable tool for the oil and gas industry. By investing in high-quality oil casing pipe, drilling companies can maximize their operational efficiency and achieve their production goals with confidence.

How to Choose the Right Well Tubing Pipe for Your Drilling Project

When it comes to drilling for oil, choosing the right well tubing pipe is crucial for the success of your project. The well tubing pipe serves as a conduit for extracting oil from the wellbore to the surface, making it an essential component of any drilling operation. With so many options available on the market, it can be overwhelming to select the best tubing pipe for your specific needs. In this article, we will discuss the factors to consider when choosing a well tubing pipe for your drilling project.

One of the first things to consider when selecting a well tubing pipe is the material it is made of. The most common materials used for well tubing pipes are Carbon Steel, Stainless Steel, and Alloy Steel. Each material has its own set of advantages and disadvantages, so it is important to choose the one that best suits your drilling conditions. Carbon steel is the most cost-effective option, but it is prone to corrosion in harsh environments. Stainless steel is more resistant to corrosion, making it ideal for offshore drilling projects. Alloy steel offers a balance of strength and corrosion resistance, making it a versatile choice for various drilling applications.

Another important factor to consider when choosing a well tubing pipe is the size and wall thickness. The size of the tubing pipe will depend on the flow rate and pressure requirements of your drilling operation. A larger diameter tubing pipe will allow for higher flow rates, while a thicker wall thickness will provide greater strength and durability. It is essential to consult with a professional engineer to determine the optimal size and wall thickness for your specific drilling project.

In addition to material and size, it is also important to consider the type of connection used in the well tubing pipe. There are several types of connections available, including threaded, coupled, and integral connections. Threaded connections are the most common and cost-effective option, but they are prone to leaks and require regular maintenance. Coupled connections provide a more secure and leak-proof seal, making them ideal for high-pressure drilling operations. Integral connections offer the highest level of strength and reliability, but they are also the most expensive option.

When selecting a well tubing pipe, it is crucial to consider the operating conditions of your drilling project. Factors such as temperature, pressure, and corrosive elements can impact the performance and longevity of the tubing pipe. It is important to choose a tubing pipe that can withstand the specific conditions of your drilling operation to ensure optimal performance and safety.

In conclusion, choosing the right well tubing pipe is essential for the success of your drilling project. By considering factors such as material, size, connection type, and operating conditions, you can select a tubing pipe that meets your specific needs and requirements. Consulting with a professional engineer and supplier can help you make an informed decision and ensure the success of your drilling operation. Remember, the well tubing pipe is the lifeline of your drilling project, so choose wisely.