Table of Contents

Cat7 Cable Customization: Advantages and Options

Cat7 Cable Customization: Advantages and Options

In the world of networking, the demand for high-quality cables is ever-present. With the advent of advanced technology and the increasing need for faster and more reliable internet connections, businesses and individuals alike are seeking out solutions that can deliver superior performance. This is where customized Cat7 cables come into play, offering a range of advantages over standard off-the-shelf options.

One of the primary benefits of opting for customized Cat7 cables is the ability to tailor them to specific requirements. Unlike pre-made cables that come in standard lengths and configurations, customized cables can be designed to exact specifications, ensuring a perfect fit for any application. Whether you need a cable of a particular length, color, or configuration, customization allows you to create a solution that meets your exact needs.

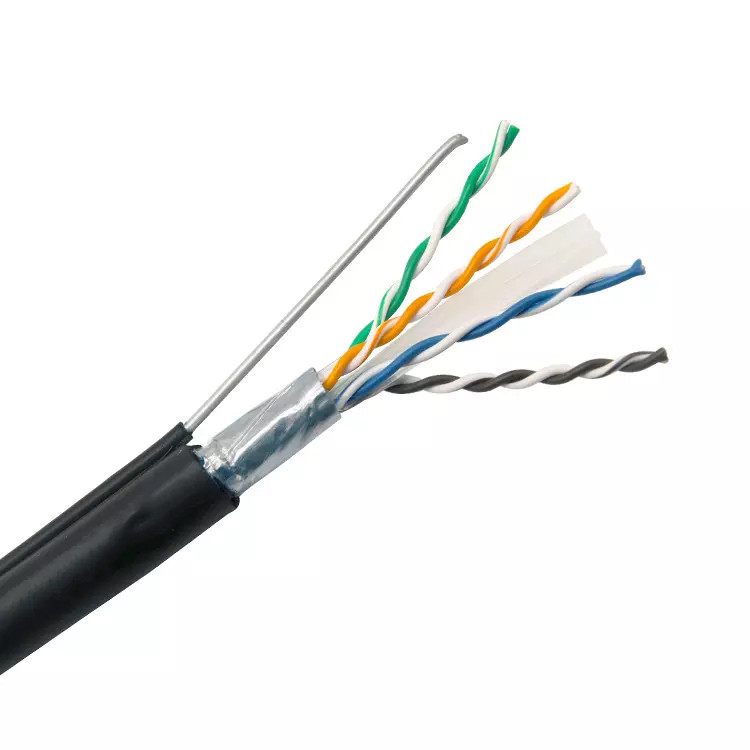

Furthermore, customization enables the incorporation of additional features and enhancements that may not be available in off-the-shelf cables. This includes specialized shielding to minimize electromagnetic interference, extra durable jackets for harsh environments, and custom labeling for easy identification. By working directly with a manufacturer, you can collaborate to develop a cable that not only meets but exceeds your expectations in terms of performance and durability.

Another advantage of opting for customized Cat7 cables is the ability to source them directly from the manufacturer. By cutting out the middleman, you can eliminate unnecessary markups and ensure a more cost-effective solution. Additionally, working directly with the manufacturer gives you greater control over the manufacturing process, allowing for faster turnaround times and more responsive customer support.

When it comes to customization options, the possibilities are virtually endless. From choosing the type of Connectors and terminations to selecting the exact gauge and type of conductors, every aspect of the cable can be tailored to your specific requirements. This level of flexibility makes customized Cat7 cables ideal for a wide range of applications, including data centers, office networks, and industrial environments.

| Serial Number | Products |

| 1 | Large Electrical Telephone Logarithmic Cable |

For those who are less familiar with the process of crimping Ethernet cables, the prospect of customization may seem daunting. However, with the right guidance and tools, crimping Cat7 cables can be a straightforward process. To begin, you will need a few key components, including a Cat7 cable, RJ45 connectors, a crimping tool, and a wire stripper.

To crimp a Cat7 cable, start by stripping away a small portion of the outer jacket to expose the individual wires. Next, carefully arrange the wires according to the desired wiring scheme, ensuring that each wire is inserted into the correct pin slot on the RJ45 connector. Once the wires are in place, use the crimping tool to firmly secure the connector onto the cable, making sure to apply even pressure to ensure a secure connection.

While crimping Cat7 cables may require some practice to master, the ability to customize your own cables offers unparalleled flexibility and control over your network infrastructure. Whether you’re a seasoned IT professional or a novice enthusiast, the satisfaction of creating a custom cable that meets your exact specifications is unparalleled.

In conclusion, customized Cat7 cables offer a range of advantages over off-the-shelf options, including the ability to tailor them to specific requirements, source them directly from the manufacturer, and incorporate additional features and enhancements. With the right tools and knowledge, crimping Cat7 cables can be a straightforward process, providing you with the flexibility and control to create a network infrastructure that meets your exact needs.

Cat6a Cable Customization: Finding the Right Factory

Cat7 cable Customization Manufacturer Directly Supply, Cat6a cable customized factory, how to crimp cat5e ethernet cable.

When it comes to networking, having the right cables is crucial. Whether you’re setting up a small home network or a large corporate infrastructure, the quality of your cables can significantly impact performance and reliability. That’s why many businesses and individuals opt for customized cables tailored to their specific needs. In this article, we’ll explore the process of finding the right factory for Cat6a cable customization.

Customization offers several advantages over off-the-shelf cables. It allows you to choose the length, color, and even the materials used in the cable construction. Additionally, customized cables can be designed to meet specific performance requirements, ensuring optimal performance in your network setup.

The first step in finding the right factory for Cat6a cable customization is research. Start by identifying reputable manufacturers with a track record of producing high-quality cables. Look for companies that specialize in networking equipment and have experience working with Cat6a cables specifically. Online reviews and testimonials can provide valuable insights into the quality of a manufacturer’s products and services.

| Serial Number | Commodity Name |

| 1 | patch cord rj45 cable |

Once you’ve compiled a list of potential manufacturers, reach out to them to discuss your customization needs. Provide detailed specifications for the cables you require, including length, color, and any specific performance requirements. A reputable manufacturer will work closely with you to understand your needs and provide customized solutions that meet your specifications.

When evaluating potential manufacturers, consider factors such as production capacity, Lead times, and pricing. You’ll want to choose a factory that can accommodate your order size and deliver within your desired timeframe. While cost is certainly a factor, it’s essential to prioritize quality and reliability when selecting a manufacturer for customized cables.

In addition to production capabilities, consider the manufacturer’s quality control processes. Look for companies that adhere to industry standards and employ rigorous testing procedures to ensure the quality and reliability of their products. This includes testing for factors such as signal integrity, impedance, and crosstalk to ensure optimal performance in real-world networking environments.

Communication is key when working with a custom cable manufacturer. Make sure the company is responsive to your inquiries and provides clear and timely updates on the status of your order. A transparent and communicative manufacturer will help ensure a smooth and hassle-free customization process from start to finish.

Once you’ve selected a manufacturer for your Cat6a cable customization needs, it’s time to finalize the details of your order. Work closely with the manufacturer to confirm specifications, pricing, and delivery timelines. Be sure to review and approve any design proofs or samples before production begins to ensure that the final product meets your expectations.

Finally, don’t forget about ongoing support and maintenance. Choose a manufacturer that stands behind their products and offers warranty coverage and support services in case of any issues or defects. This will provide you with peace of mind knowing that your customized cables are backed by reliable support.

In conclusion, finding the right factory for Cat6a cable customization requires careful research and consideration. By identifying reputable manufacturers, communicating your customization needs effectively, and prioritizing quality and reliability, you can ensure that your customized cables meet your specifications and deliver optimal performance in your network setup.

How to Crimp Cat5e Ethernet Cable Like a Pro

In the realm of networking, the ability to create custom Ethernet cables is a valuable skill. Whether you’re setting up a home network or tackling a large-scale installation, knowing how to crimp Cat5e Ethernet cables can save time and money while ensuring optimal performance. Cat5e (Category 5e) cables are a common choice for Ethernet connections due to their reliability and affordability. Learning to crimp Cat5e cables properly requires attention to detail and practice, but with the right tools and technique, you can achieve professional results.

Before diving into the crimping process, it’s essential to gather the necessary materials. You’ll need Cat5e Ethernet cable, RJ45 connectors, a crimping tool, wire cutters/strippers, and optionally, a cable tester. Quality materials are crucial for ensuring a reliable connection, so invest in reputable brands for your cables and connectors.

Begin by stripping approximately 1.5 inches of the outer jacket from the end of the Cat5e cable using wire strippers. Be careful not to nick the inner wires during this process, as it could affect the cable’s performance. Once the outer jacket is removed, you’ll find four twisted pairs of wires inside. Untwist each pair and arrange the wires according to the T568B wiring standard, which is the most commonly used wiring scheme for Ethernet connections.

With the wires arranged in the correct order, trim any excess length to ensure they are all uniform in size. Insert the trimmed wires into the RJ45 connector, making sure each wire reaches the end of the connector and aligns with the corresponding pin slot. Double-check the wiring sequence to avoid any mistakes that could cause connectivity issues.

Once the wires are securely in place, insert the connector into the crimping tool and apply firm pressure to crimp the connector onto the cable. Make sure the connector is fully seated in the tool before crimping to ensure a proper connection. Repeat the process for the other end of the cable if needed.

After crimping both ends of the cable, it’s time to test the connection. If you have a cable tester, use it to check for continuity and verify that each wire is properly connected. Alternatively, you can plug the cable into a device and test for connectivity by transferring data or establishing a network connection.

With practice, you’ll become more proficient at crimping Cat5e Ethernet cables, allowing you to customize cables to the exact lengths needed for your network setup. Custom cables not only eliminate excess clutter but also minimize signal interference and improve overall network performance.

In conclusion, mastering the art of crimping Cat5e Ethernet cables is a valuable skill for anyone involved in network installation or maintenance. By following the proper procedure and using quality materials, you can create custom cables that meet your specific requirements and ensure reliable connectivity for your network infrastructure. Practice regularly to refine your technique, and you’ll soon be crimping cables like a pro.