Table of Contents

Understanding the GOST 8732-78 Standard for Hot-Deformed Carbon Steel Seamless Pipes in Oil and Gas Industry

The GOST 8732-78 standard is a critical benchmark in the oil and gas industry, specifically for hot-deformed carbon steel seamless pipes. This standard, established by the Russian Federation, sets the technical requirements for seamless hot-deformed pipes made of carbon steel. Understanding the GOST 8732-78 standard is essential for professionals in the oil and gas industry, as it ensures the quality, Safety, and efficiency of these crucial components.

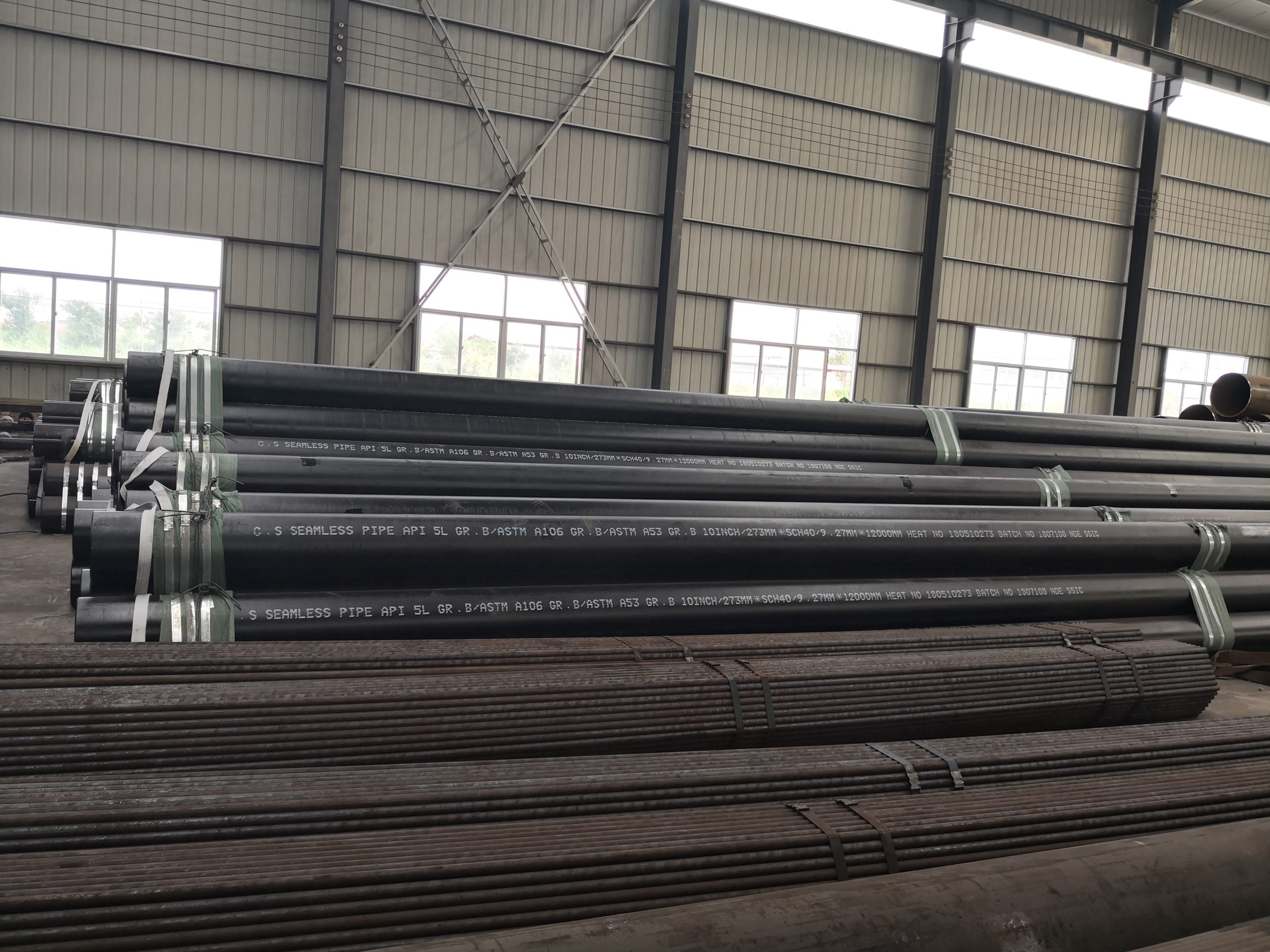

The GOST 8732-78 standard primarily focuses on the chemical composition, mechanical properties, and manufacturing methods of hot-deformed carbon steel seamless pipes. These pipes are typically used in high-pressure applications, such as oil and gas transportation, where durability and reliability are paramount. The standard ensures that these pipes can withstand the rigors of such demanding environments.

The chemical composition of the pipes, as stipulated by the GOST 8732-78 standard, is a key factor in their performance. The standard specifies the maximum and minimum percentages of various elements, including carbon, silicon, and manganese, that the steel can contain. This precise control over the chemical composition ensures that the pipes have the necessary strength and ductility for their intended applications.

In addition to the chemical composition, the GOST 8732-78 standard also outlines the mechanical properties that the pipes must possess. These include yield strength, tensile strength, and elongation. Yield strength refers to the maximum stress that the material can withstand without permanent deformation, while tensile strength is the maximum stress that it can withstand before breaking. Elongation, on the other hand, measures the material’s ability to stretch without breaking. These properties are crucial in determining the pipe’s ability to withstand the high pressures typically encountered in oil and gas applications.

The manufacturing methods of the pipes are another critical aspect covered by the GOST 8732-78 standard. The standard specifies that the pipes should be made through hot deformation, a process that involves heating the steel to a high temperature and then deforming it to the desired shape. This method ensures that the pipes have a seamless construction, which enhances their strength and durability.

The GOST 8732-78 standard also includes provisions for testing and inspection to ensure that the pipes meet the specified requirements. These tests include chemical analysis, mechanical testing, and non-destructive testing methods such as ultrasonic and radiographic testing. The standard also specifies the marking and documentation requirements for the pipes, ensuring traceability and accountability.

In conclusion, the GOST 8732-78 standard plays a vital role in the oil and gas industry by setting the technical requirements for hot-deformed carbon steel seamless pipes. By stipulating the chemical composition, mechanical properties, and manufacturing methods of these pipes, the standard ensures their quality, safety, and efficiency. Furthermore, the standard’s provisions for testing and inspection ensure that these requirements are met, thereby guaranteeing the reliability of these crucial components in high-pressure applications. Therefore, a thorough understanding of the GOST 8732-78 standard is essential for professionals in the oil and gas industry.