Table of Contents

Exploring the Rich Heritage of Italian Knitwear Manufacturers: A Deep Dive into Tradition and Innovation

Exploring the Rich Heritage of Italian Knitwear Manufacturers: A Deep Dive into Tradition and Innovation

Italy, renowned for its rich cultural heritage and artistic craftsmanship, stands as a beacon of excellence in the realm of fashion and textile manufacturing. Among its many treasures, Italian knitwear holds a distinguished place, embodying centuries of tradition and innovation. From the rolling hills of Tuscany to the bustling streets of Milan, Italian knitwear manufacturers have mastered the art of blending heritage techniques with cutting-edge technology to produce some of the finest garments in the world.

At the heart of Italy’s knitwear industry lies a deep-rooted tradition passed Down through generations. For centuries, skilled artisans have meticulously crafted garments using techniques handed down from master to apprentice. This tradition of craftsmanship remains a cornerstone of Italian knitwear manufacturing, ensuring each piece bears the unmistakable mark of quality and attention to detail.

One of the most revered materials in Italian knitwear is cashmere, prized for its unparalleled softness and luxurious feel. Italy’s long-standing relationship with cashmere dates back to the 13th century when traders first introduced the Fiber to the region. Since then, Italian artisans have refined their techniques, elevating cashmere production to an art form. Today, Italy stands as a global leader in cashmere manufacturing, with companies like Loro Piana and Brunello Cucinelli setting the standard for excellence.

The allure of Italian knitwear lies not only in its rich heritage but also in its ability to embrace innovation. While traditional techniques remain integral to the manufacturing process, Italian knitwear manufacturers are also at the forefront of technological advancements. From state-of-the-art Knitting Machines to cutting-edge design Software, Italy’s knitwear industry seamlessly blends tradition with innovation to meet the demands of the modern market.

In recent years, there has been a growing trend towards sustainable and ethical manufacturing practices within the fashion industry, and Italian knitwear manufacturers are no exception. Many companies have implemented eco-friendly initiatives, such as using organic fibers and reducing water consumption, to minimize their environmental impact. Additionally, there is a renewed focus on fair labor practices, ensuring that workers are treated ethically and compensated fairly for their skills.

Despite the challenges posed by globalization and fast fashion, Italy’s knitwear industry remains resilient, adapting to changing trends while staying true to its roots. Collaborations with renowned designers and innovative marketing strategies have helped Italian knitwear manufacturers stay relevant in an increasingly competitive market.

As consumer preferences continue to evolve, Italian knitwear manufacturers are poised to meet the demand for quality, craftsmanship, and sustainability. By embracing tradition and innovation, Italy’s knitwear industry not only preserves its rich heritage but also paves the way for a more sustainable and ethical future.

In conclusion, Italian knitwear manufacturers represent the epitome of tradition and innovation in the world of fashion. Through centuries of craftsmanship and a commitment to excellence, they have established themselves as global leaders in the production of high-quality garments. By blending heritage techniques with cutting-edge technology and embracing sustainable practices, Italy’s knitwear industry continues to thrive in a rapidly changing market landscape. As we look to the future, one thing is certain: the allure of Italian knitwear will endure for generations to come.

Understanding the Importance of Anti-Corrosion Galvanized Round Pipes in Factory Settings

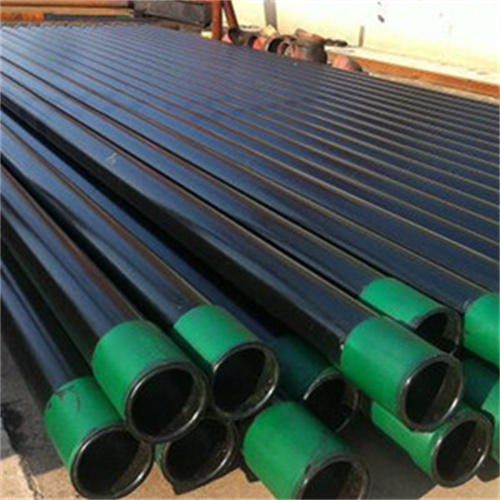

In the realm of industrial infrastructure, the integrity and durability of materials used are paramount. Among the various components crucial for ensuring structural resilience and longevity, the choice of piping material stands out as particularly significant. In this context, anti-corrosion galvanized round pipes emerge as a cornerstone element in factory settings, offering a robust solution to combat corrosion and enhance the longevity of Steel Structures.

Corrosion poses a persistent threat to metal components, particularly in environments characterized by moisture, Chemicals, and other corrosive agents commonly found in industrial settings. Left unchecked, corrosion can Lead to structural degradation, compromising the Safety, reliability, and operational efficiency of factory facilities. Recognizing this challenge, engineers and manufacturers have turned to anti-corrosion measures such as galvanization to fortify steel against the corrosive onslaught.

Galvanization involves the application of a protective Zinc coating to steel surfaces, forming a barrier that shields the underlying metal from corrosive elements. This process significantly enhances the corrosion resistance of steel, making it an ideal choice for various industrial applications, including piping systems in factories. The galvanization process can be executed through different methods, with hot-dip galvanization being one of the most widely employed techniques due to its effectiveness and durability.

Hot-dip galvanized round pipes are manufactured by immersing Steel Pipes into a bath of molten zinc, ensuring complete coverage of the surface with a uniform zinc coating. This meticulous process creates a metallurgical bond between the zinc coating and the steel substrate, providing unparalleled corrosion protection even in the harshest industrial environments. As a result, hot-dip galvanized pipes have become synonymous with reliability and longevity in factory infrastructure, offering a cost-effective solution for mitigating corrosion-related risks.

One of the primary applications of hot-dip galvanized round pipes in factory settings is in greenhouse steel structures. Greenhouses play a vital role in modern Agriculture, providing controlled environments for optimal plant growth and cultivation. However, the humid and corrosive conditions prevalent in greenhouse environments can pose a significant challenge to structural integrity over time. Hot-dip galvanized pipes address this challenge by offering superior corrosion resistance, ensuring the durability and longevity of greenhouse frameworks.

Beyond greenhouse applications, anti-corrosion galvanized round pipes find widespread use in various factory settings, including manufacturing plants, Warehouses, and industrial facilities. These pipes serve as critical components in conveying fluids, gases, and other materials essential for industrial processes. By safeguarding against corrosion-induced failures, galvanized pipes contribute to uninterrupted operations, enhanced safety, and reduced maintenance costs, thus bolstering overall productivity and efficiency.

In addition to corrosion resistance, hot-dip galvanized round pipes offer other desirable properties, including high strength, impact resistance, and ease of installation. These attributes further underscore their suitability for demanding factory environments where reliability and performance are non-negotiable. Moreover, galvanized pipes boast a long service life, minimizing the need for frequent replacements and associated downtime, thereby optimizing operational continuity and cost-effectiveness.

In conclusion, the utilization of anti-corrosion galvanized round pipes, particularly through hot-dip galvanization, plays a pivotal role in enhancing the resilience and longevity of steel structures in factory settings. By providing robust protection against corrosion, galvanized pipes ensure the integrity of critical infrastructure, safeguarding against structural failures and operational disruptions. As factories continue to evolve and expand, the importance of employing corrosion-resistant materials like galvanized pipes cannot be overstated, underscoring their indispensable role in sustaining industrial progress and prosperity.