Table of Contents

Exploring the Process of Manufacturing Baby Cable Knit Sweaters in a Factory Setting

The process of manufacturing baby cable knit sweaters in a factory setting is a complex and intricate one that involves multiple steps and skilled workers. From selecting the materials to packaging the final product, each stage requires precision and attention to detail to ensure a high-quality end result.

The first step in the manufacturing process is selecting the materials. High-quality Yarn is essential for creating a soft and durable sweater that will be comfortable for a baby to wear. The yarn is typically made from natural fibers such as wool or cotton, which are known for their warmth and breathability. Once the yarn has been selected, it is carefully inspected for any defects or inconsistencies before being used in the production process.

After the yarn has been inspected and approved, it is time to begin the knitting process. This is where the intricate cable knit pattern is created, using specialized Knitting Machines that are programmed to produce the desired design. Skilled operators oversee this process, ensuring that each sweater is knit to the correct size and specifications.

Once the sweaters have been knit, they are carefully inspected for any imperfections or errors. Any issues are quickly addressed and corrected before the next stage of the manufacturing process begins. This attention to detail is crucial for maintaining the high quality standards that customers expect from a baby cable knit sweater.

| better sweater manufacturer | knitted kids cardigan Producer |

| school sweaters manufacturer | sweaters sueter manufacturer |

| men’s designer sweaters Maker | \u00a0mujer sweater Maker |

| square pattern sweater Maker | color sweater Producer |

After the sweaters have been inspected and approved, they are washed and blocked to shape. This helps to ensure that the sweaters maintain their shape and size after being worn and washed by the baby. Once the sweaters have been washed and blocked, they are dried and pressed to remove any wrinkles or creases.

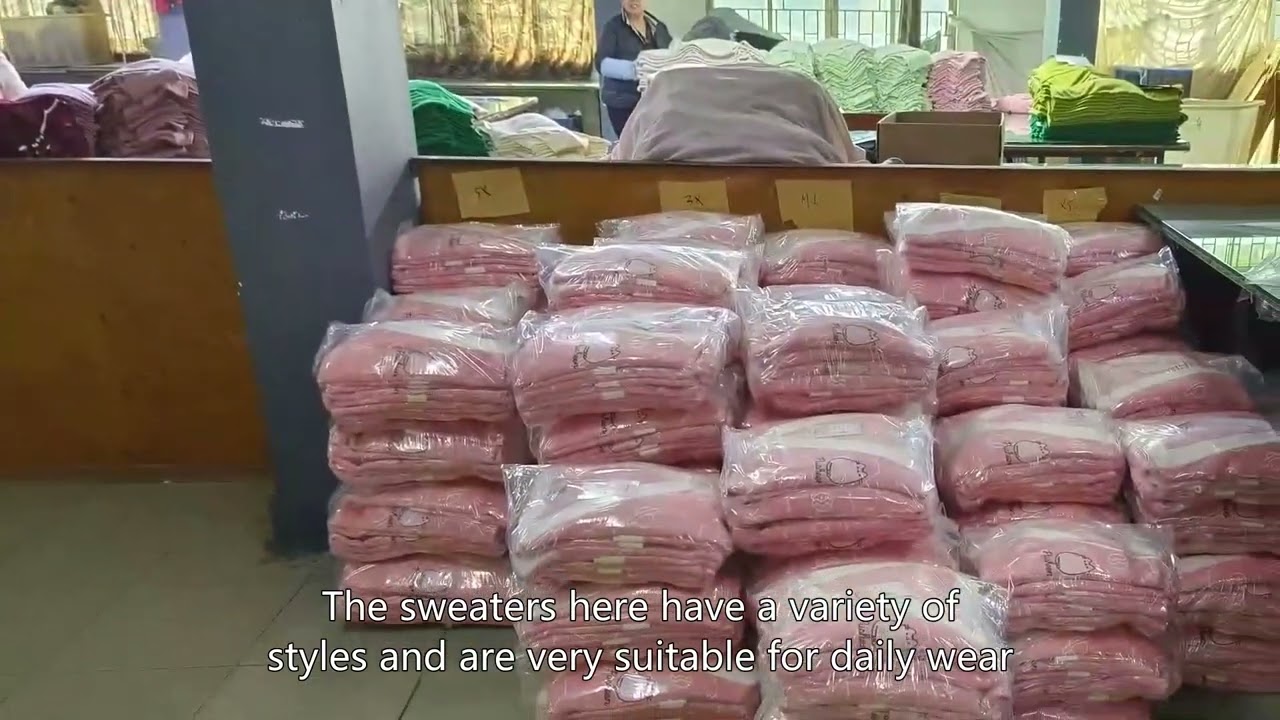

The final stage of the manufacturing process is packaging the sweaters for distribution. Each sweater is carefully folded and placed in a protective plastic bag to keep it clean and free from damage during shipping. Labels with important information such as size, care instructions, and country of origin are attached to each sweater before they are packed into boxes for transport.

Throughout the entire manufacturing process, quality control measures are in place to ensure that each sweater meets the highest standards of craftsmanship and durability. Skilled workers carefully monitor each stage of production, making adjustments as needed to maintain consistency and quality.

In conclusion, the process of manufacturing baby cable knit sweaters in a factory setting is a complex and detailed one that requires skill, precision, and attention to detail. From selecting the materials to packaging the final product, each stage of production plays a crucial role in creating a high-quality sweater that will keep babies warm and comfortable. By following strict quality control measures and employing skilled workers, factories can ensure that each sweater meets the highest standards of craftsmanship and durability.