Table of Contents

Overview of API Steel Oil Pipe, Coupling, Tubing, and Casing in Oilfield Service

Overview of API Steel Oil Pipe, Coupling, Tubing, and Casing in Oilfield Service

In the oil and gas industry, the use of high-quality equipment is paramount to ensure the safe and efficient extraction of oil from the ground. API steel oil pipe, coupling, tubing, and casing play a crucial role in this process. These components are specifically designed to withstand the harsh conditions of the oilfield and ensure the smooth flow of oil from the well to the surface.

API, which stands for American Petroleum Institute, sets the standards for the manufacturing and testing of oilfield equipment. API steel oil pipe, coupling, tubing, and casing adhere to these strict standards to ensure their reliability and durability. Let’s take a closer look at each of these components and their importance in oilfield service.

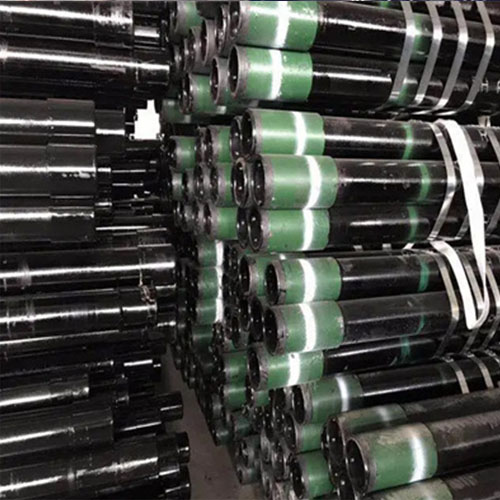

API steel oil pipe is a hollow cylinder made of steel that is used to transport oil and gas from the well to the surface. It is available in various sizes and grades to accommodate different well conditions. The steel used in API oil pipes is known for its high strength and resistance to corrosion, making it ideal for the demanding conditions of the oilfield.

Couplings are used to connect two pipes together, ensuring a secure and leak-proof connection. API steel couplings are specifically designed to withstand high pressure and temperature variations. They are manufactured with precision to ensure a tight fit and prevent any leakage that could Lead to environmental and Safety hazards.

Tubing is a smaller-sized pipe that is inserted into the well to extract oil and gas. It is crucial for the efficient production of oil from the reservoir. API steel tubing is designed to withstand high-pressure environments and harsh conditions. It is available in various sizes and grades to meet the specific requirements of different oil wells.

Casing is a large-diameter pipe that is installed in the well to provide structural support and prevent the collapse of the wellbore. It also isolates different geological formations and prevents the mixing of fluids. API steel casing is highly durable and resistant to corrosion, ensuring the integrity of the well throughout its lifespan.

In oilfield service, the proper selection and installation of API steel oil pipe, coupling, tubing, and casing are essential for the success of the operation. These components must meet the stringent standards set by the API to ensure their reliability and performance. Regular inspections and maintenance are also crucial to detect any defects or deterioration in the equipment and address them promptly to avoid any potential risks.

In conclusion, API steel oil pipe, coupling, tubing, and casing are vital components in oilfield service. Their high-quality construction and adherence to API standards ensure the safe and efficient extraction of oil from the ground. These components