Table of Contents

Understanding API 5CT Coupling Specifications for Casing and Tubing

API 5CT coupling and threads play a crucial role in the oil and gas industry, specifically in the context of casing and tubing. Understanding the specifications and standards set by the American Petroleum Institute (API) is paramount for ensuring the integrity and efficiency of these components in drilling operations.

API 5CT, established by the API, outlines the technical requirements for casing and tubing used in the exploration and production of oil and Natural Gas. These specifications cover various aspects, including dimensions, mechanical properties, chemical composition, and testing procedures. Among these specifications, coupling and threads are fundamental components that facilitate the connection and sealing of casing and tubing strings.

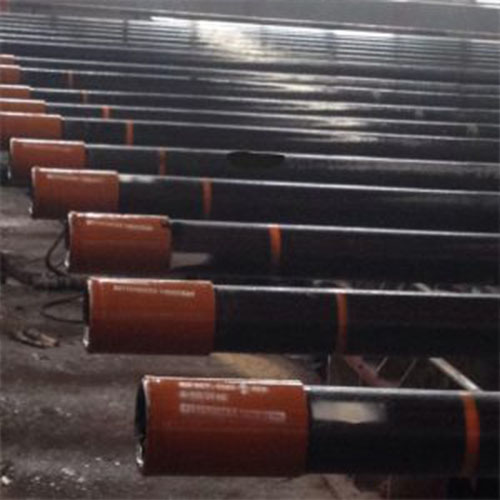

Couplings in API 5CT are designed to join two lengths of casing or tubing together securely. They provide the necessary mechanical strength to maintain the integrity of the wellbore under challenging downhole conditions, such as high pressure and temperature. Moreover, couplings ensure proper alignment and support for the threaded connections, minimizing the risk of leaks or failures during operation.

Threaded connections are a critical feature of API 5CT coupling specifications. These threads are precision-engineered to create a tight seal between adjacent casing or tubing joints, preventing the escape of fluids and maintaining well integrity. The threads must meet stringent dimensional and geometric tolerances to ensure compatibility and reliability in various downhole environments.

API 5CT specifies different types of threads for casing and tubing applications, including external (round) and internal (non-upset) threads. External threads are typically used for casing, providing enhanced strength and resistance to axial loads. Internal threads, on the other hand, are common in tubing applications, offering improved hydraulic efficiency and ease of installation.

One of the key considerations in API 5CT coupling specifications is the Thread form. The thread form refers to the shape and profile of the threads, which must conform to specific standards to ensure proper engagement and sealing. Common thread forms include buttress, tapered, and non-tapered designs, each offering distinct advantages in terms of load-bearing capacity and sealing performance.

Moreover, API 5CT establishes guidelines for thread pitch, Lead, and taper to facilitate optimal performance and compatibility with wellhead equipment and tools. These parameters are critical for achieving a secure and leak-free connection between casing and tubing strings, reducing the risk of costly downtime and environmental hazards associated with fluid loss or wellbore instability.

In addition to thread form and dimensions, API 5CT coupling specifications also address material requirements and manufacturing processes. Couplings must be fabricated from high-quality steel alloys that exhibit excellent mechanical properties, corrosion resistance, and toughness in harsh downhole conditions. Furthermore, stringent quality control measures are implemented to ensure consistency and reliability in every coupling produced.

Overall, API 5CT coupling and thread specifications are essential for maintaining the integrity and efficiency of casing and tubing systems in oil and gas wells. By adhering to these standards, operators can minimize the risk of equipment failure, optimize drilling performance, and maximize the productivity of their assets. As the industry continues to evolve, advancements in coupling technology and manufacturing processes will further enhance the reliability and longevity of downhole components, driving innovation and efficiency in the oil and gas sector.